Transformers are important power equipment, and their safe operation directly affects normal production and daily life. The aging and deterioration caused by long-term operation of transformers have become the main factor in the occurrence of faults. In recent years, there have been multiple transformer overheating incidents in power plants and substations, resulting in fires and widespread power outages. Previously, the power system had manual inspections for power outage maintenance, but now it has evolved to online maintenance that can monitor the status.

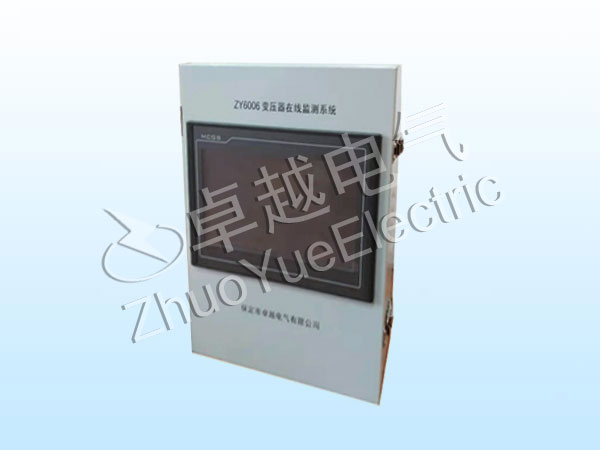

Product Features

◆ Is a comprehensive online monitoring device that integrates online monitoring of transformer inlet and outlet joint temperature, oil temperature, iron core grounding current, cable grounding current, load side voltage and current monitoring, light and heavy gas monitoring, and video monitoring. The monitoring host collects data such as transformer inlet and outlet temperature, operating oil temperature, iron core grounding current, and cable sheath grounding current, and uploads them to the cloud platform through GPRS.

◆ It can remotely monitor the operation data of the transformer and set alarm thresholds for each data. If it exceeds the limit, the platform can automatically push SMS alarm prompts, playing a role in reminding management personnel to handle it in a timely manner.

◆ Real time data of on-site transformers can be viewed and displayed in real-time charts.

The system includes rich historical data viewing and management functions that can be accessed and viewed at any time to view transformer operation history data, and supports export and printing for archiving.

Home

Home Tel

Tel Product

Product